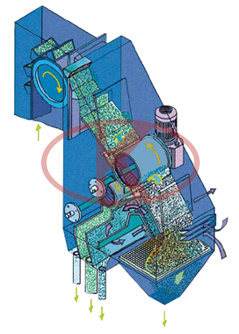

Shot blast strengthening equipment abrasive recycling system

Scraper conveyer

Rolling brush is made up of axis-linked reducer, idler pulley assembly,brush cover and brush. Drive position adopts axis linked reducer that is of impact structure and convenient for maintenance.

When rolling brush is rotating at high speed, high-intension nylon rolling brush will sweep up sands into screw conveyor that will convey the sands flowing through the two sides of steel plate into the bottom of cabinet and get into sands recycle system.

Imported nylon brush is of big elasticity, good anti-abrasion. The service life is more than 3000hours.

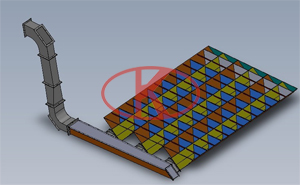

Honeycomb floor recycling system

The honeycomb floor recycling system consists of a series of feeding hopper and grating board laid on it. Between the hoppers recycling pipe is formed, used shot and scrap will be sent by the recycling pipe to a adjustable vortex separator for shot and dust separating.

Honeycomb floor recycling system applies to small shot blasting room(10~20m2) and place of low recycling volume(about 2T/h), especially for non-metal shot.

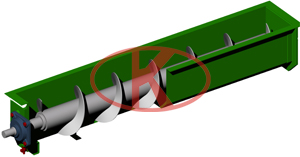

Screw conveyor

It consists of cycloidal reducer, spiral shaft, shell and bearing with seat, etc. it is a common shot conveyor equipment, which is an important component of shot blasting circulation system.

The screw conveyor is our series part, with stable and reliable performance. The whole screw blade is 16Mn material, the special process makes the spacing and circle very accurate and lifetime is extended.

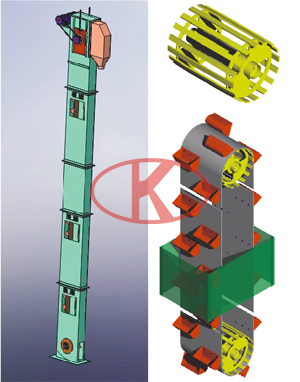

Hopper elevator

It mainly consists of upper/lower transmission, barrel, belt, and hopper and so like.

The shell is of bending- formed welding structure, with access door on the side to maintain and replace hopper. Both front and side of the lower shell is fixed with movable door to maintain lower transmission and remove bottom jammed sands.

Sand falling is by centrifugal gravity.

Squirrel-cage roller, a little protruding in the middle, not only improves the friction between elevating belt and pulley to avoid skid phenomenon of old-fashioned bear pulley, but reduce the pretension force as well and extents its service life. Furthermore, it can prevent sands from blocking between lower pulley and belt that will make belt run to one side. Sands will flow through the gap between the spoke and the belt.

Elevating capacity should leave 10% allowance,

Shot blast strengthening equipment abrasive separating system

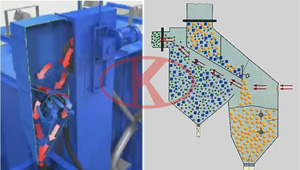

Shot and dust separator

This machine is an advanced air-curtain type dust&sand separator, consisting of rotary sieve, sand container and driver.

The mixture of sand and dust from the bucket elevator will be carried to rotary sieve by the separator's screw. The rotary seperator has internal and external screw blades. In operating conditions, the internal screw blades will send big sand and waste to the debris outlet to be discharged. The mixture of sand and dust after separated will be propelled by external screw blades along the longitude direction to be disturbed, then through the adjustment of separator baffle plate, the dust and sand will be in the flow-curtain state, evenly flowing to the bottom of the separator. At this time, the dust removing fan will draft air from air outlet of separator and can effectively separate sands from dust and tiny wastes by the gravity cyclone separation principle.

Dust will be discharged through the air duct and sand shots will fall into bottom to be reserved, thus achieving shots recycling.

Magnetic separating system

The magnetic separating system is the best selection for large amount of sand after separating shot blasting treatment. Shanghai Liangshi magnetic system is a shot and sand separating system of great efficiency, widely used in the world casting industry, meanwhile used in updating the equipment and increase productivity of shot blaster. The magnetic separating system is adjustable, eternal magnet can go through the magnetic roller overcoat to draw the metal shot, then the magnetic roller overcoat with metal shot continue to rotate from magnetic field to the non-magnetic field, where the metal shot is sent to another separator and stored. The separated sand and remained shot are conveyed to the two stage magnetic separation for another separation, the remained separated sand will be lower than 0.2%.

Shot dimension separating (vibrating screen)

Vibrating screen separator standard configuration is two layer screens, the upper screen can separate rough impurities to the scrap barrel, the lower screen can separate unqualified shots to the scrap barrel.

Features as follows:

High filtering efficiency, high precision

The sieve will not block up, finest can be 400 mesh, mesh changing is quick

Good sealant, low noise, no dust pollution

Small volume, light weight, convenient to move, selective of discharging direction

Simple to maintain, can be used by single/multi layers, highest four layers, contacting part with material is stainless steel.

Shot separating ( Screw separator)

The peening media is mostly round, if the used shot is broken, it must be removed to prevent reusing to damage the surface of workpiece. The shot media must have even dimension, as the strength to impact on the part by media can be different, it is directly related with the weight and eject speed. If shots of different dimensions are mixed together, larger shots can produce deeper residual pressure stress layer then the smaller shots, the uneven residual stress can result in the inconsistency of strengthening effect.

To separate the unqualified shots, a special screw sieve separating system is used. The principle is using the rotating of inner ring and out ring to separate the round shots and broken shots by their different rotating speed.

cartridge filter

KLT series cartridge filter consists of dust cabin, cabinet, fan, air pipe, filter cartridge, impulse valve, pulse instrument and support. Quick clamping sealing structure is used for dust cabin, with wheels under the bottom, to ensure dust not escaping outside during cleaning dust.

The filter cartridge is of folded cylinder structure, outer diameter of 325mm, inner diameter of 220mm, cylinder high of 660mm. A standard filter area of cartridge is 16m2, while that of bag filter with same shape is only 0.7m2.

One layer of submicron ultra-thin fiber adheres on the common filter material and the arrangement between the fibers of adhesion layer are very close, the clearance of which is only 1% of bottom layer fiber. Extremely small sieve hole can block a majority of submicron particles outside surface of filter material to prevent them from into inside fiber at bottom layer. Therefore, forming a good breathable dust layer at the beginning is to keep low resistant and effective. Because the dust cannot get deep into filter material inside, it is characterized by low resistant and convenient for dust cleaning, which cannot be compared with by a bag filter.